Subscriber Benefit

As a subscriber you can listen to articles at work, in the car, or while you work out. Subscribe NowOne of the new laws to emerge from the state’s 2023 legislative session could attract new advanced recycling companies to Indiana, something industry advocates and lawmakers hope results in less plastic going to landfills and more jobs and investment coming into the state.

Senate Enrolled Act 472 passed 94-1 in the Indiana House of Representatives and 44-5 in the Senate before being signed by Gov. Eric Holcomb in April.

The new law defines “advanced recycling” as a manufacturing process for the conversion of post-use polymers and recovered feedstocks into basic raw materials, feedstocks, chemicals and other products.

Further, according to SEA 472, an advanced recycling facility is defined as a manufacturing facility that receives, stores and converts post-use polymers and recovered feedstocks resulting from advanced recycling and is subject to regulation by the Indiana Department of Environmental Management.

That means the polymers and feedstocks are not defined as solid waste, and advanced recycling companies are not required to obtain a solid waste license.

Sen. Mark Messmer, R-Jasper, authored the bill.

Messmer told Indiana Lawyer that SEA 472 comes on the heels of House Enrolled Act 1226, a 2022 bill that established the Central Indiana Waste Diversion Pilot Project and dealt with the repurposing of industrial solid waste. He said the bills addressed the same lack of rulemaking by IDEM.

Late in the 2022 legislative session, Messmer said Brightmark Energy, an advanced recycling company with a site in the northeast Indiana town of Ashley, approached him about drafting what became SEA 472 to codify their plastic recycling process as a manufacturing process.

“I just felt it was a substantial enough addition to the bill (HEA 1226) that I thought it merited a standalone bill,” Messmer said.

What is advanced recycling?

There are 40 advanced recycling companies in the United States, with Brightmark Energy being the only one located in Indiana. Also, Messmer said there are some Indiana manufacturing companies — like Berry Global in Evansville and SABIC in Mount Vernon — that use advanced recycling plastic materials in their products.

There are 40 advanced recycling companies in the United States, with Brightmark Energy being the only one located in Indiana. Also, Messmer said there are some Indiana manufacturing companies — like Berry Global in Evansville and SABIC in Mount Vernon — that use advanced recycling plastic materials in their products.

Through its chemical processes, Brightmark Energy can take any type of plastic and turn it into raw materials for reuse, as opposed to putting the plastic in a landfill or incinerating it.

“You’re taking pressure and heat and taking complex plastic products and breaking them down to their raw materials,” Messmer said.

A spokesman for Brightmark Energy declined a request for an interview with Indiana Lawyer.

In an Inside Indiana Business profile of the company in 2022, company CEO Bob Powell said the $260 million facility in Ashley had already recycled 4 million pounds of plastics near the end of the startup phase of the Ashley facility, including 4,000 car seats, 60,000 pounds of boat wrap and 6,000 pounds of plastics recovered from the ocean.

When fully operational, the plant was expected to divert 100,000 tons of plastics annually.

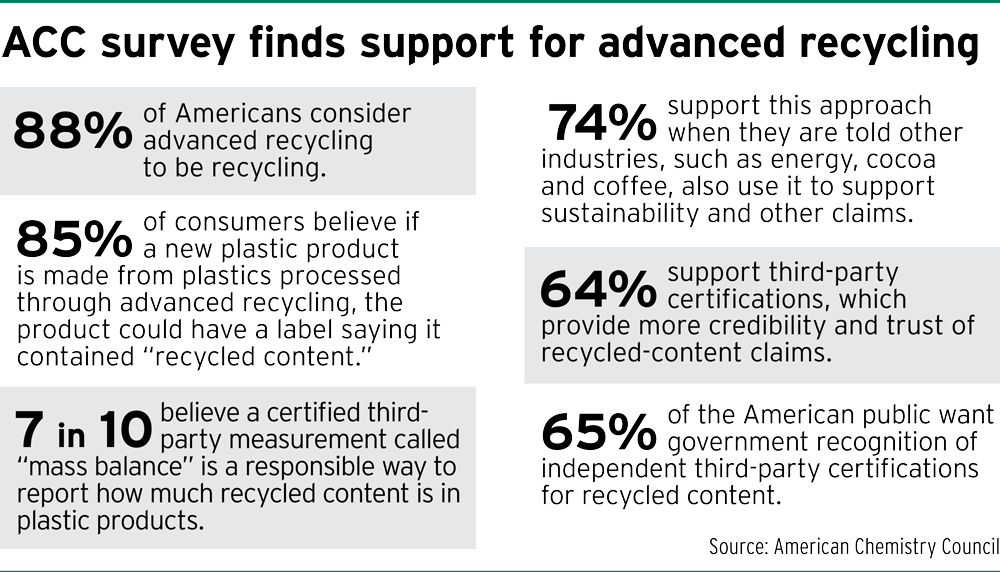

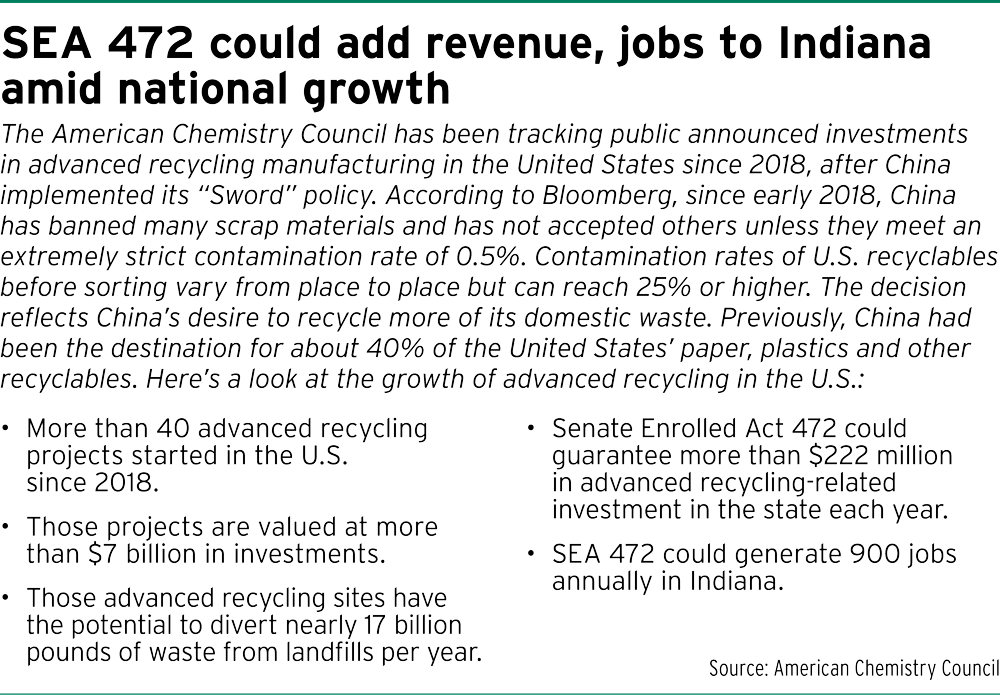

Craig Cookson, senior director of plastics sustainability for the American Chemistry Council, said there have been more than 40 advanced recycling projects in the U.S. since 2018, with those projects valued overall at more than $7 billion in investments.

Cookson said Berry Global and SABIC are ACC members with an interest in seeing more advanced recycling facilities open to give them better access to recycled plastics. Those companies, as well as Brightmark, want to shore up their supply chains, he said.

With the passage of SEA 472, Indiana joined Ohio, Kentucky and other regional states in passing legislation regarding the regulation of advanced recycled facilities as manufacturing facilities.

“There’s definitely been interest in some of these other states,” Cookson said, noting Indiana was the 21st state to pass an advanced recycling law.

Advanced recycling sites can recycle plastics like tubes, pouches and films that traditional mechanical recycling facilities can’t break down, Cookson explained. The facilities turn those plastics into basic plastic feedstocks, which manufacturers can reuse.

With SEA 472 becoming law, Cookson said Indiana could potentially become a hub for advanced recycling.

An ACC analysis estimated that if 50% of plastics going to incinerators and landfills in Indiana were diverted, it would result in an economic impact of more than $200 million annually to the state, with the creation of approximately 900 new jobs.

Concerns from lawmakers, environmentalists

Although the bill passed by overwhelming margins in the Indiana House and Senate, there were some lawmakers and environmentalists with questions about advanced recycling and its potential environmental impacts.

At an Indiana Senate Environmental Affairs Committee meeting to discuss the legislation, Sen. Shelli Yoder, D-Bloomington, said she was concerned because she’d heard about the high heat needed to break down plastics in the advanced recycling process, resulting in higher greenhouse gas emissions.

“It is not having the positive impact with the exchange of needing to break it down with such high heat as well as the chemicals that are involved,” Yoder said.

Cookson disputed Yoder’s statement and said industry officials were very confident advanced recycling results in a net environmental benefit and a reduction in greenhouse gas emissions.

Yoder asked Cookson if advanced recycling released additional microplastics into the environment.

He responded that there was no additional release of microplastics. Further, he said there would be a “char” left over from the process that can be safely landfilled after being tested.

He responded that there was no additional release of microplastics. Further, he said there would be a “char” left over from the process that can be safely landfilled after being tested.

“Those will be well-regulated by IDEM,” Cookson said.

Tim Maloney of the Hoosier Environmental Council said he appreciated the intent of the bill and supported the concept of turning plastic waste into a usable product and keeping it out of the environment.

“We do see some opportunities with this,” Maloney said, adding, “but (we) do have some concerns as well.”

According to Cookson, SEA 472 ensures regulatory certainty, and advanced recycling could count toward the state’s recycling goals.

According to IDEM, Indiana has a 50% recycling goal for municipal solid waste, or MSW, and requires mandatory reporting of solid waste and recycling data to track progress, but does not have a set date to achieve the results. The current MSW generation has a 21% recycling rate and needs to divert from disposal another 2.7 million tons for reduce, reuse and recycling to meet the recycling goal.

Cookson also said the law ensures advanced recycling facilities are governed by IDEM, the Clean Air Act, the Clean Water Act and other applicable regulations for manufacturers.

According to Messmer, about 7 billion tons of plastic waste products have been converted into commercial reuse in the U.S.•

Please enable JavaScript to view this content.